Quick Details

| Place of Origin: |

Hebei, China (Mainland)

|

Brand Name: |

Jiurong

|

Model Number: |

JZ51

|

| Material: |

Steel

|

Packaging & Delivery

| Packaging Details: | couplers in carton boxes and threading machine in wooden cases |

| Delivery Detail: | 15-30 days after received your down payment |

Specifications

rebar splicing coupler and threading machine

1 Diameter from 12mm to 50mm

2 Professional solution to different rebar splicing

Features of rebar mechanical splicing technology

1.High-strength of splicing:Meeting the requirements in JGJ107 ,ACI318, BS8110, DIN1045, UBC1997, NF A35-020

2.Excellent anti-fatigue nature:Having passed 2 million times' fatigue experiments.

3.Good thread form and high precision of screw thread:the splicing quality is stable and reliable.No fake thread is produced.

4.Wide range of application:applicable to the same or different diameter rebars'(12-50mm) connection in any

directions and positions.

5.High-speed construction:The screw thread head can be made before constructing to ensure the rebars to be

connected on site.

6.Environmental friendly construction procedure:The construction site is safe and reliable,free from any pollution.

7.Energy saving:The rated power of the equipment is 3-4Kw only,no need to use special electric power facilities.

8.Excellent anti-low-temperature nature:Having passed -40 Degree Celsius low temperature test.

9.Construction under all weather conditions practicable:not influenced by such weather conditions as wind,rain or snow.

10.Manufactured under strict quality standard ISO9001:2000.

11.Full traceability of material origin and production batch.

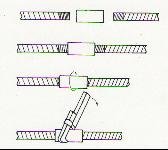

Different Mechanical Splicing Methods of Rebar

Type A:

When the connecting bar can be rotated.

Consisting of 2 standard threads and 1 coupler.

The first bar is fully engaged inside the coupler (at the production line).

The assembly is completed by rotating the connecting inside the coupler until full engagement.

Type B:

When the connecting bar is too long or too heavy to turn.

Consisting of 1 standard thread,1 left hand thread,1 right-and-left thread coupler

The two bars are placed in position,The assembly is completed by turning the wrench until full engagement.

Type C:

When the connecting bars have different diameters.

Consisting of 2 standard thread and 1 different diameter coupler.

The first bar is fully engaged inside the different diameter coupler(at the production line).

The assembly is completed by rotating the connecting bar inside the coupler until full engagement.

Type W: Weldable ( connected with steel column)

Consisting of 1 standard thread and 1 weldable coupler

A weldable coulper is welded onto a steel member.

The assembly is completed by rotating the connecting bar inside the coupler until full engagement.